Single-Strand Aluminum Wiring — What It Is & Why It’s Controversial

-

Definition: Single-strand (solid) aluminum conductors used on 15 A/20 A branch circuits feeding outlets, lights, and switches.

-

Root of the reputation: Failures historically occurred at connections (devices, splices), not in the cable run. Older AA-1350 alloy wire and steel-screw devices were especially prone to loose, high-resistance joints that run hot. Modern AA-8000 aluminum behaves better, but correct terminations are still critical. U.S. Consumer Product Safety CommissionIAEI Magazine

BC/Canada context: The Canadian/BC Electrical Code permits aluminum conductors when installed and terminated with approved materials per code and manufacturer instructions. Aluminum wiring itself isn’t banned; the focus is on proper terminations. Government of British ColumbiaESASafe

Homeowner action checklist

-

Don’t assume “automatic fail.” Treat it as a system needing verification and, often, upgrades.

-

Plan to have a licensed electrician (FSR) assess every termination.

-

Gather insurance questions early—some carriers want proof of inspection or remediation. bcaa.com

Electrical — How to Identify Aluminum Branch Wiring

-

Look for “ALUMINUM, AL, ALUM” on exposed cable sheaths near the panel or in unfinished areas.

-

Branch-circuit aluminum is typically #12 AWG on 15 A and #10 AWG on 20 A circuits.

-

Devices may be marked CO/ALR (rated for aluminum). ebs.safetycodes.ab.caESASafe

Homeowner action checklist

-

Photograph labels/markings at the panel and in accessible spaces.

-

Note warm faceplates, flickering lights, or intermittent power—key symptoms of loose terminations.

Electrical — Warning Signs & BC Climate Factors

-

Symptoms: Warm or discoloured outlets/switches, buzzing, flicker, a “hot” or acrid smell, frequently tripping breakers—often worse when large loads run.

-

BC climate stresses: Salt-laden coastal air (oxidation) and winter cold snaps (thermal cycling) can aggravate marginal joints, especially in older devices.

-

AFCI/GFCI: Helpful added protection but not a substitute for correcting poor terminations. blog.technicalsafetybc.caTechnical Safety BC

Homeowner action checklist

-

If a device feels hot or smells burnt, switch off the breaker and call an electrician.

-

Don’t tighten device screws “just because”—improper torque can worsen aluminum connections.

Electrical — Acceptable Repair & Upgrade Paths in BC

-

Copper pigtailing at each device

-

Use CSA-certified Al/Cu connectors (e.g., Ideal Twister Al/Cu Model 65, CSA C22.2 #188), antioxidant compound, and correct torque. This adapts aluminum branch conductors to new copper-only devices. Ideal Ind

-

-

AlumiConn lug connectors

-

Miniature lug-style connectors recognized by the U.S. CPSC for aluminum repairs; also listed to UL/Canadian specs. Availability varies—confirm CSA acceptance locally. King InnovationLowe's

-

-

CO/ALR-rated devices

-

Replace receptacles/switches with CO/ALR (copper-aluminum revised) devices that are specifically rated for aluminum terminations. Many pros still prefer pigtailing to copper for flexibility and future device compatibility. Eaton

-

-

Full copper rewire

-

Most permanent (and often best for resale/insurance), but most disruptive and costly.

-

Note: The U.S. CPSC has documented hazards with some twist-on splices in aluminum; if used, they must be the specific CSA-certified Al/Cu connectors and installed exactly as directed. Many Canadian electricians/insurers favour AlumiConn or copper rewiring over generic twist-ons. U.S. Consumer Product Safety CommissionIdeal Ind

Homeowner action checklist

-

Ask your electrician which CSA-certified method they’ll use and why.

-

Request written documentation (device list, connector types, torque values if recorded).

Electrical — Permits, Code & Insurance in BC

-

Permits & inspections: Electrical work in BC generally requires a Technical Safety BC permit (or municipal permit where applicable). Homeowners can sometimes pull their own permits, but aluminum remediation is best handled by a licensed contractor/FSR. BC LawsTechnical Safety BC

-

Code edition: BC adopts the Canadian Electrical Code, Part I via the BC Electrical Code Regulation; ensure work aligns with the current 2024/2025 adoption. Government of British ColumbiaCity of Victoria

-

AFCI/GFCI locations & alterations: See Technical Safety BC bulletins clarifying Section 26 requirements when altering existing branch circuits. Technical Safety BC

-

Insurance: Many BC insurers will write policies on homes with aluminum if you provide proof of a licensed inspection and remediation (e.g., pigtailing, CO/ALR devices). Expect surcharges without documentation; requirements vary by company—ask your broker before renewal. bcaa.comESASafe

Homeowner action checklist

-

Confirm your AHJ (municipality vs. Technical Safety BC) and pull the correct permit.

-

Get a post-upgrade inspection report you can share with your insurer.

-

Consider upgrading to AFCI/GFCI where code requires when devices are replaced. Technical Safety BC

Electrical — Step-by-Step Aluminum Branch Circuit Assessment (BC Homeowner)

-

Panel-area visual only (cover on): Note cable markings; do not remove the deadfront unless qualified.

-

Sample devices: An electrician should pull a representative set of outlets/switches to examine terminations for oxidation, looseness, or heat damage.

-

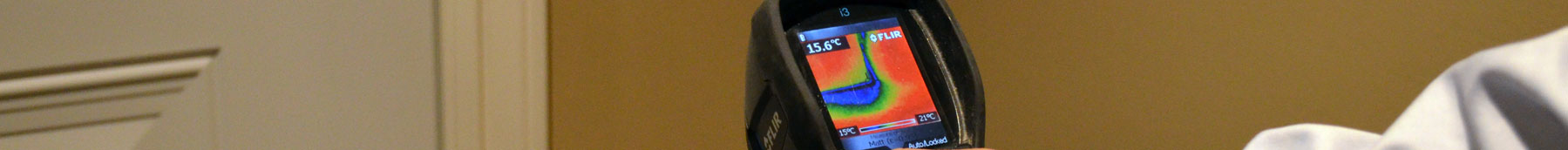

Thermal scanning (optional): Helps spot hot connections under load.

-

Choose a remediation strategy: Copper pigtails with CSA Al/Cu connectors, AlumiConn, CO/ALR devices, or full rewire.

-

Permit & documentation: Obtain permit, complete work, pass inspection, and file reports for insurance. Technical Safety BCBC Laws

Homeowner action checklist

-

Hire a licensed electrician familiar with aluminum remediation.

-

Keep invoices, product cut-sheets (e.g., Ideal Model 65), and inspection approvals in a home file. Ideal Ind

Electrical — Maintenance Timelines

-

Every 3–5 years: Pro electrician to spot-check outlets/switches on high-load circuits (kitchen, bath, laundry, living room entertainment).

-

Immediately after renovations: Re-inspect any circuits that were extended or devices replaced.

-

After extreme events: Post-seismic work or water intrusion near devices—inspect and correct as required.

Homeowner action checklist

-

Log the date and scope of each check.

-

Re-label the panel as upgrades are completed.

Safety Note

Working inside energized panels, re-terminating aluminum, and torqueing lugs are not DIY tasks. Obtain permits and use a licensed electrical contractor; improper work can lead to fire or insurance issues. BC Laws

Real-life BC scenario

A homeowner on Vancouver Island adds a hot tub and ties into aluminum feeders with connections not specified by the manufacturer. High-resistance joints overheat and a control box burns. The investigation attributes the failure to aluminum used where copper was required by the equipment—illustrating how critical correct conductor type and terminations are. Technical Safety BC

Quick Reference — Homeowner Aluminum Wiring Checklist

-

Confirm presence of single-strand aluminum wiring (photos of markings).

-

Book a licensed electrician familiar with aluminum remediation.

-

Decide on pigtails (CSA Al/Cu connectors), AlumiConn, CO/ALR devices, or rewire. Ideal IndKing Innovation

-

Pull the required permit; schedule inspections. BC Laws

-

Add AFCI/GFCI where required; label circuits. Technical Safety BC

-

File documentation for insurance. bcaa.com

-

Plan 3–5-year rechecks, sooner if issues reappear.

Sources & further reading

-

BC Electrical Code adoption & permits: Province of BC; Technical Safety BC homeowner permits and bulletins. Government of British ColumbiaTechnical Safety BC+1

-

Aluminum allowed when properly terminated: Electrical Safety Authority (Ontario) public guidance. ESASafe+1

-

Connector/device standards: CSA C22.2 No. 42 (devices); CSA-certified Al/Cu connectors (Ideal Model 65). Standards Council of CanadaIdeal Ind

-

Hazard background & repair methods: U.S. CPSC on aluminum branch circuits; IAEI on AA-8000 vs AA-1350 alloys. U.S. Consumer Product Safety CommissionIAEI Magazine